Title: “Innovations in Injection Moulds: Enhancing Manufacturing Precision”

Title: “Innovations in Injection Moulds: Enhancing Manufacturing Precision”

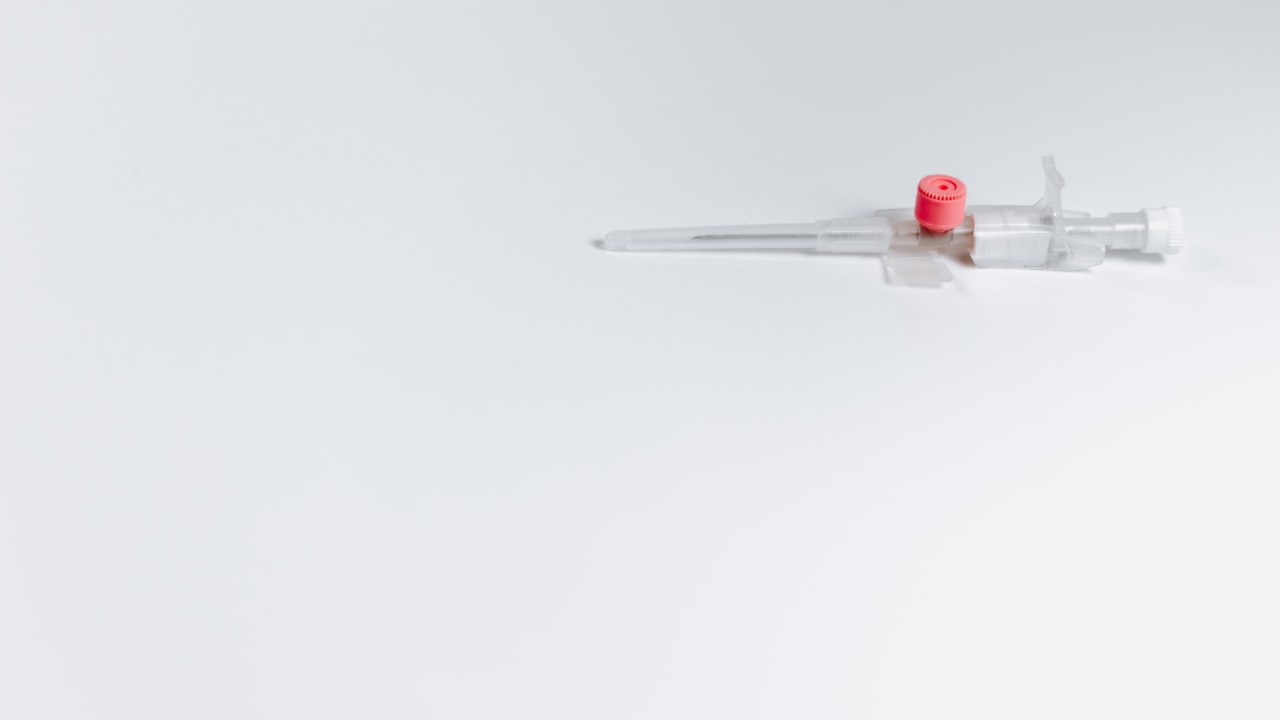

Injection moulds play a crucial role in the manufacturing industry, especially in the production of plastic parts. As technology continues to advance, injection mould factories are constantly innovating to enhance manufacturing precision and efficiency. In this competitive market, choosing the right injection mould supplier is essential for achieving high-quality production output.

One key innovation in injection moulds is the use of advanced design software and simulation tools. These technologies allow engineers to create intricate mould designs with precision and accuracy. By simulating the injection moulding process before production begins, potential issues can be identified and resolved, resulting in smoother manufacturing processes and higher-quality parts.

Another innovation in injection moulds is the development of high-speed, high-precision moulding machines. These machines are equipped with cutting-edge features such as real-time monitoring systems and automated quality control mechanisms. This not only improves the overall efficiency of the injection moulding process but also ensures consistent part quality throughout production runs.

Furthermore, the use of innovative materials in injection moulds has revolutionized the industry. From high-performance steels to advanced coatings, these materials increase the durability and lifespan of moulds, reducing maintenance costs and downtime. Additionally, the incorporation of conformal cooling technology in injection mould design optimizes cooling efficiency, resulting in shorter cycle times and improved part quality.

When selecting an injection mould supplier, it is essential to consider their expertise, experience, and track record. A reputable supplier should have a team of skilled engineers and technicians who are knowledgeable about the latest industry trends and technologies. They should also provide excellent customer support and offer customized solutions to meet specific manufacturing requirements.

In conclusion, innovations in injection moulds are driving the manufacturing industry towards greater precision and efficiency. By leveraging advanced design tools, high-performance machines, innovative materials, and expert suppliers, manufacturers can achieve higher-quality production output and stay competitive in the market. Choosing the right injection mould supplier is crucial for success in today’s fast-paced manufacturing environment.