Title: Designing High-Quality Injection Molds: Key Considerations and Best Practices

Title: Designing High-Quality Injection Molds: Key Considerations and Best Practices

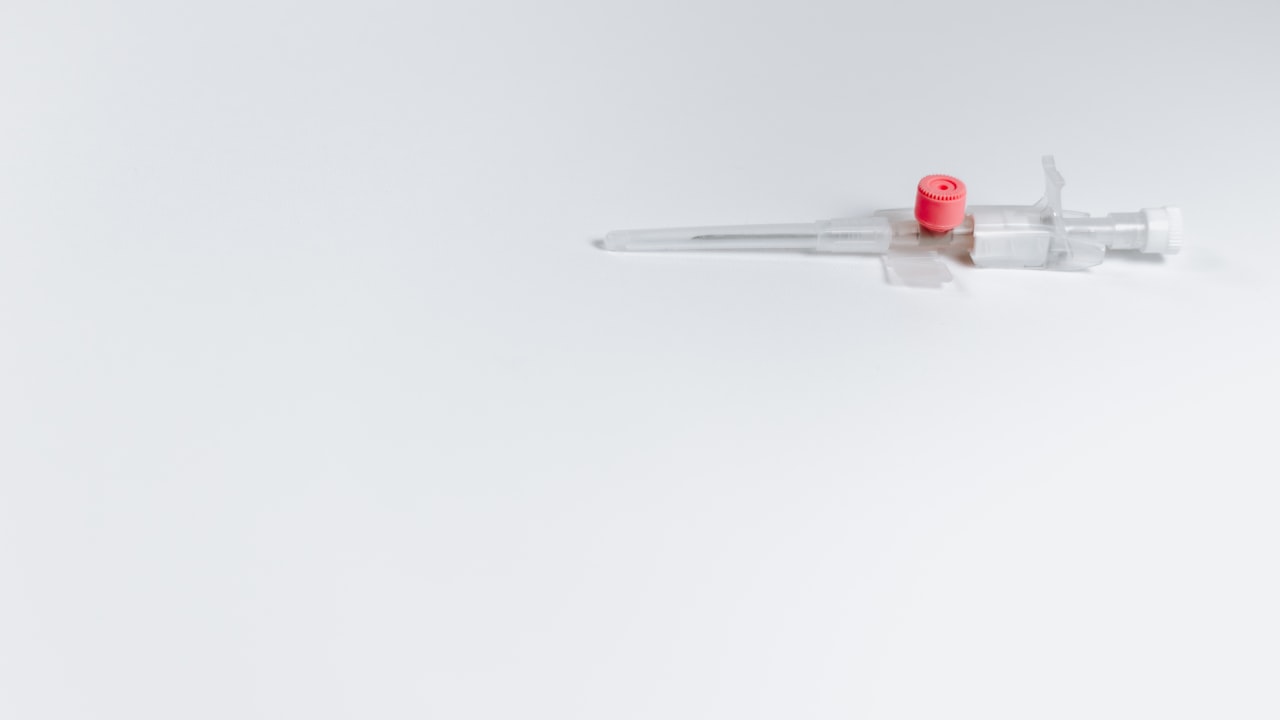

Injection molds play a crucial role in the manufacturing process of a wide range of products. Choosing the right injection mold factory and supplier is essential to ensuring the production of high-quality parts. The design of the injection mold is a critical factor that directly impacts the quality and efficiency of the molding process.

When selecting an injection mold factory, it is important to consider their reputation, experience, and capabilities. A reputable factory will have a track record of delivering high-quality molds that meet the customer’s specifications. Experience in designing and manufacturing molds for different industries and applications is also an important factor to consider. Additionally, the factory’s capabilities in terms of technology, equipment, and workforce play a crucial role in determining the quality of the molds they produce.

Working with a reliable injection mold supplier is equally important. The supplier should have a deep understanding of the specifications and requirements of the injection mold, as well as the materials and processes involved. Clear communication between the supplier and the factory is essential to ensure that the mold design meets the customer’s expectations and is manufacturable.

In the design phase of an injection mold, several key considerations and best practices should be followed to ensure the production of high-quality molds. One important consideration is the material selection. The type of material used for the mold will depend on the part being produced, the production volume, and other factors. The material should have good wear resistance, thermal conductivity, and dimensional stability to ensure the longevity and quality of the mold.

Another key consideration in mold design is the cooling system. Efficient cooling is essential to ensure proper part solidification and ejection, as well as to minimize cycle times. The design of the cooling channels should allow for uniform cooling across the mold cavity to prevent warping and defects in the final part.

In conclusion, designing high-quality injection molds requires collaboration between the injection mold factory, supplier, and customer. By following key considerations and best practices in mold design, manufacturers can ensure the production of high-quality parts that meet the customer’s requirements and specifications.