Title: “The Evolution and Innovation of Injection Molds in Modern Manufacturing”

Title: “The Evolution and Innovation of Injection Molds in Modern Manufacturing”

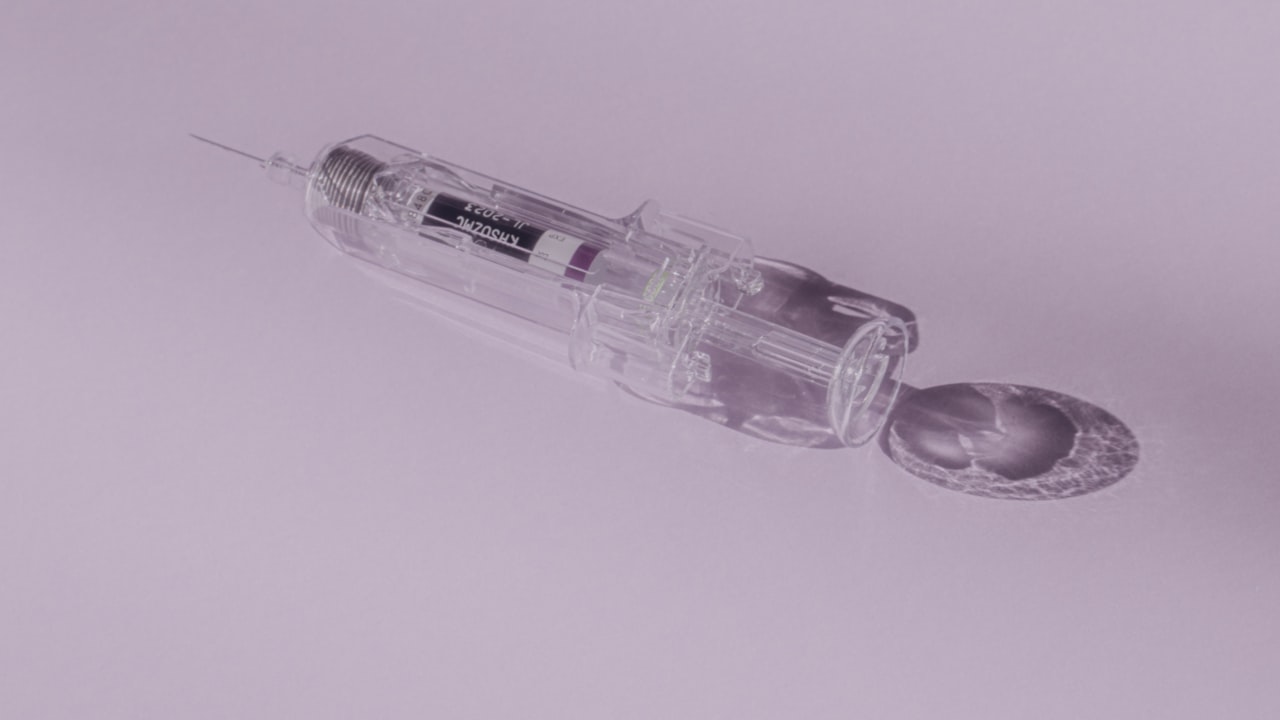

Injection molds play a crucial role in the manufacturing industry, enabling the mass production of intricate plastic components with high precision and efficiency. With the advancement of technology and increasing demands for customized products, injection molds have undergone significant evolution and innovation in recent years.

Injection mold factories are at the forefront of these developments, constantly striving to improve their manufacturing processes and capabilities. By investing in state-of-the-art machinery and adopting advanced design software, injection mold suppliers are able to produce molds with greater complexity and faster turnaround times. This not only benefits the manufacturers but also allows for more flexibility in design and production.

One of the key advancements in injection mold technology is the use of 3D printing. This additive manufacturing process allows for the rapid prototyping of molds, reducing lead times and costs significantly. Injection mold suppliers are increasingly incorporating 3D printing into their workflow to create intricate mold designs that were previously considered unfeasible. This innovation has opened up new possibilities in product development and design.

Furthermore, the integration of IoT (Internet of Things) technology in injection molds has revolutionized the way manufacturers monitor and maintain their molds. Smart injection molds are equipped with sensors that collect data on temperature, pressure, and cycle times in real-time. This data is then transmitted to a centralized system, allowing for predictive maintenance and minimizing downtime.

In conclusion, the evolution and innovation of injection molds have transformed the manufacturing industry, making it more efficient, cost-effective, and versatile. As injection mold suppliers continue to push the boundaries of technology, we can expect to see even more exciting developments in the field of injection molding in the years to come.

Title: The Importance of Injection Molds in Manufacturing Processes

Title: The Importance of Injection Molds in Manufacturing Processes