Title: “Revolutionizing Manufacturing with Injection Molds: Innovation and Efficiency”

Title: “Revolutionizing Manufacturing with Injection Molds: Innovation and Efficiency”

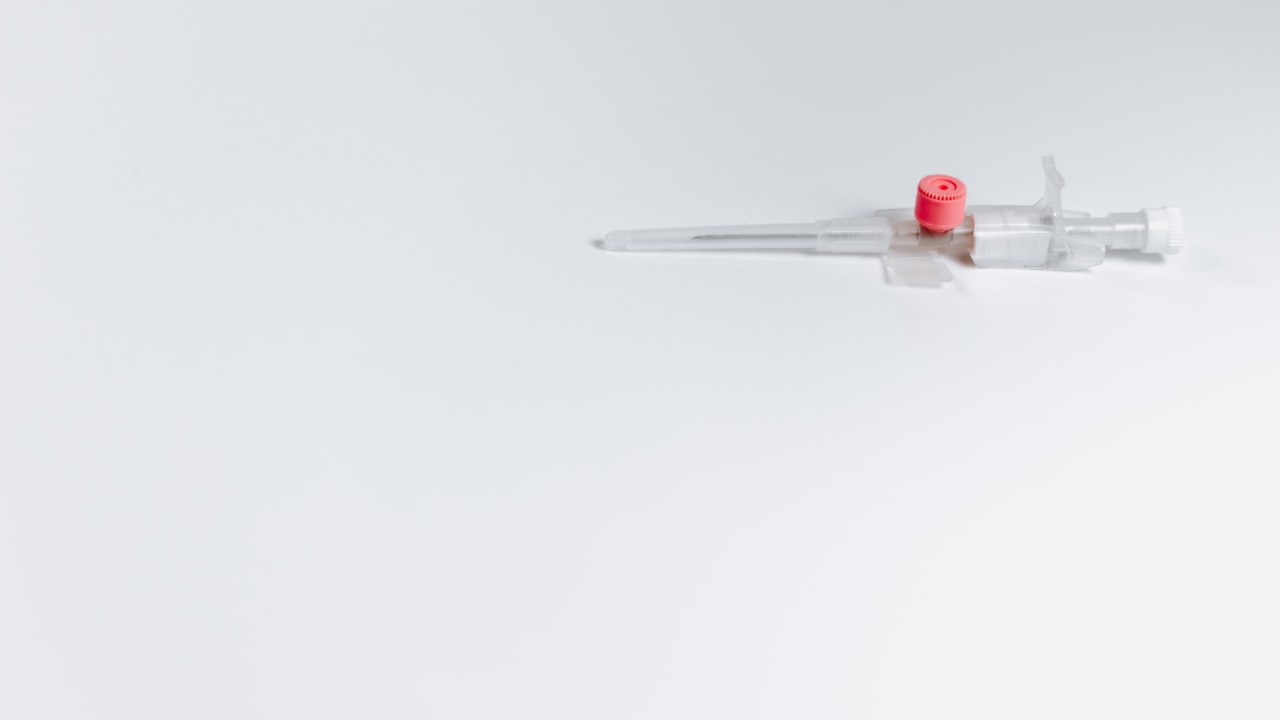

Injection molds play a crucial role in the manufacturing industry, enabling the mass production of various products with high efficiency and precision. In recent years, the development of injection mold factories and suppliers has revolutionized the way products are designed and produced.

Injection mold factories serve as the backbone of the manufacturing process, providing the necessary tools and expertise to create molds that are customized to the specific requirements of each product. These factories utilize advanced technology and machinery to design and produce high-quality injection molds that can withstand the rigors of mass production.

The role of injection mold suppliers is equally vital, as they are responsible for providing manufacturers with the necessary molds to produce their products. Injection mold suppliers work closely with manufacturers to understand their needs and specifications, offering a wide range of mold options to suit different production requirements.

With the advancements in injection mold technology, manufacturers now have access to a wide range of materials and design options to create products that are both innovative and cost-effective. Injection molds can be tailored to produce complex shapes and intricate details, allowing manufacturers to bring their creative vision to life.

Furthermore, the efficiency of injection molds has significantly improved, reducing production time and costs for manufacturers. By streamlining the production process and minimizing waste, injection molds have helped companies increase their productivity and competitiveness in the market.

In conclusion, injection molds have played a transformative role in the manufacturing industry, driving innovation and efficiency in product production. With the continuous advancements in technology and the expertise of injection mold factories and suppliers, manufacturers can expect to see further improvements in product design and production processes in the future.

Title: “Revolutionizing Manufacturing: Unleashing the Potential of Injection Molding Molds”

Title: “Revolutionizing Manufacturing: Unleashing the Potential of Injection Molding Molds” Title: “Exploring the Efficiency and Innovation of Injection Molds in Manufacturing”

Title: “Exploring the Efficiency and Innovation of Injection Molds in Manufacturing” Title: “The Impact of Injection Molds in Manufacturing Processes”

Title: “The Impact of Injection Molds in Manufacturing Processes” Title: Revolutionizing Plastic Manufacturing: The Importance of Injection Molds

Title: Revolutionizing Plastic Manufacturing: The Importance of Injection Molds Title: “Innovations in Injection Moulds: Enhancing Manufacturing Precision”

Title: “Innovations in Injection Moulds: Enhancing Manufacturing Precision” Title: Revolutionizing Manufacturing: The Impact of Injection Molds

Title: Revolutionizing Manufacturing: The Impact of Injection Molds Title: The Innovation and Efficiency of Injection Molds in Modern Manufacturing

Title: The Innovation and Efficiency of Injection Molds in Modern Manufacturing