Title: The Importance of Injection Molds in Manufacturing Processes

Title: The Importance of Injection Molds in Manufacturing Processes

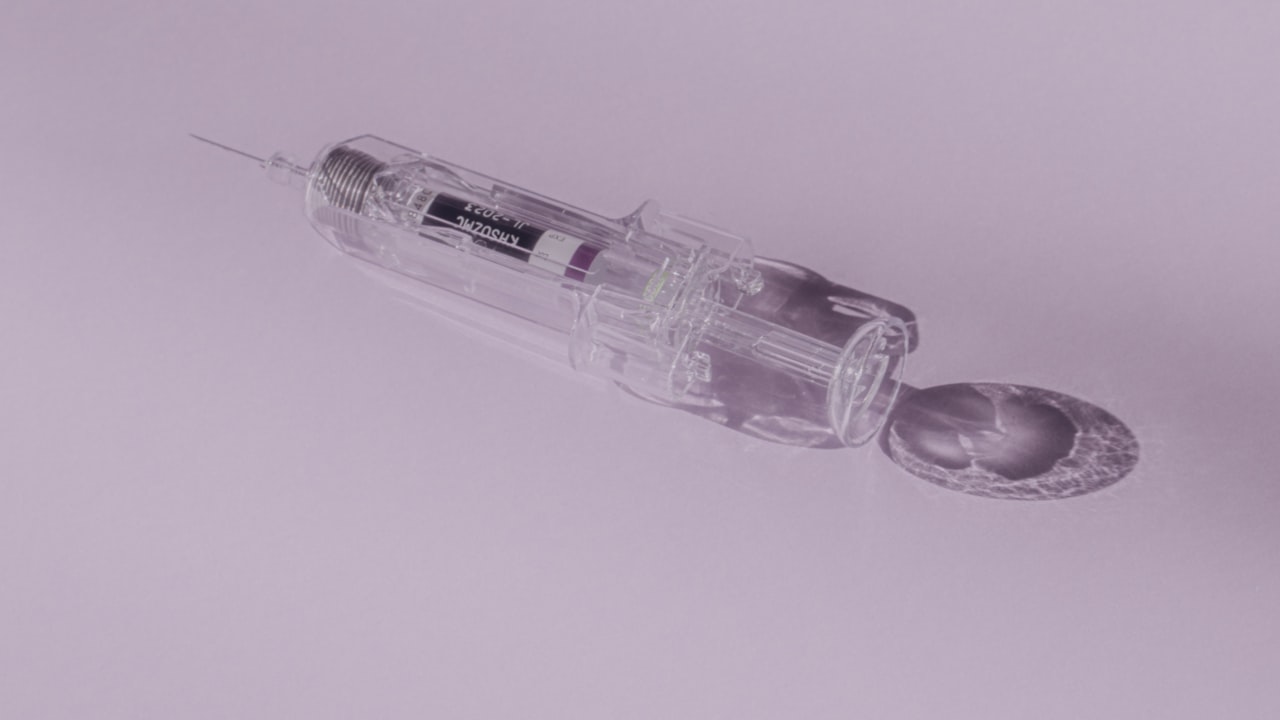

Injection molds are an integral part of the manufacturing industry, playing a crucial role in the production of a wide variety of products that we use in our daily lives. Manufacturers rely on injection molds to create everything from simple household items to complex components used in high-tech industries. Let’s delve into the significance of injection molds and how they have revolutionized the manufacturing process.

Injection molds, also known as injection molding tools, are specially designed and manufactured to produce plastic parts through the injection molding process. These molds are typically made from high-quality steel or aluminum and are customized to meet the specific requirements of each product. Injection molds are fundamental in ensuring the precision, quality, and consistency of the final products.

In today’s competitive manufacturing landscape, finding the right injection mold factory or supplier is crucial for achieving success. An experienced and reputable injection mold factory will have the expertise and technology to design and manufacture high-quality molds that meet strict industry standards. Working with a reliable injection mold supplier can streamline the production process and ensure that the molds are delivered on time and within budget.

The advantages of using injection molds in manufacturing processes are numerous. Injection molding offers high efficiency and cost-effectiveness, making it an attractive option for mass production. The ability to create complex geometries and intricate shapes with precision sets injection molding apart from other manufacturing methods. Additionally, injection molds allow for quick cycle times, resulting in faster production rates and shorter lead times.

There are several types of injection molds available, each suited for different production requirements. Single-cavity molds are ideal for small production runs, while multi-cavity molds are used for high-volume production. Family molds, which contain multiple cavities of different parts in a single mold, are cost-effective for producing related components simultaneously.

The latest advancements in injection mold technology, such as the integration of 3D printing for rapid prototyping and mold manufacturing, have further enhanced the efficiency and flexibility of the injection molding process. 3D printing allows manufacturers to quickly iterate on mold designs and produce prototypes for testing before committing to mass production.

In conclusion, injection molds are indispensable in the manufacturing industry, enabling manufacturers to produce high-quality products efficiently and cost-effectively. By understanding the importance of injection molds and working with experienced suppliers, manufacturers can stay competitive in today’s fast-paced market.